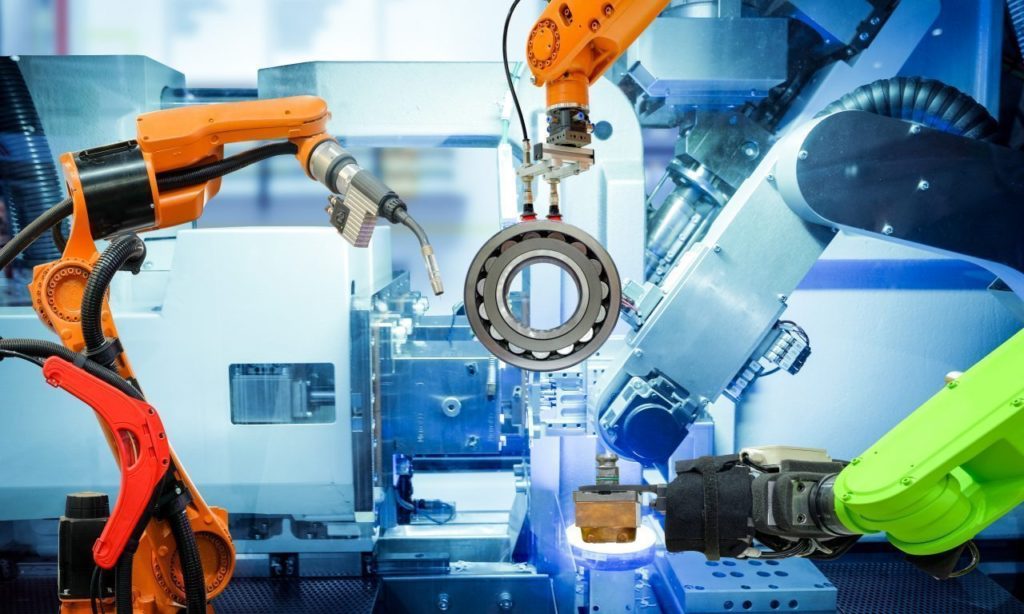

While the advent of robotics has given rise to many concerns, the technology has numerous benefits for the manufacturing industry. This technology is cheap and can be easily programmed, making it a great fit for smaller batches. This technology can also be used in many niches, enabling it to be efficient and cost-effective for certain tasks. These robots can be guided by their vision, making them easy to program. This technology is a game changer for many industries and will soon be used in manufacturing plants across the world.

Modern robotics is based on computer vision, which is a method of analyzing light or electromagnetic radiation using solid-state physics. Image sensors use theories of quantum mechanics and optics to understand light propagation and image formation. In addition, robots can be equipped with multiple vision sensors to better calculate the depth of their environment. To enable them to accurately navigate and perform tasks, robots’ eyes must be able to focus on an area of interest and adapt to variations in light intensity.

The goal of robotics is to replace human labour in a wide variety of manufacturing applications. In most commercial robotic applications, robots will replace humans. However, some industries may use robots to augment human labour. For example, a robot could assist human workers with repetitive tasks that humans aren’t equipped to handle. With advanced safety systems, robots can even work alongside humans in manufacturing environments. Further, companies may use robotics to rebalance their production lines.

With the rise of robots, the production of these machines has increased. In fact, the average price of a robot has dropped by about half in real terms, in relation to labor costs. This development has been helped by the rise of the demand for these robots in emerging economies. In addition to this, robots have a higher retention rate than their human counterparts. The development of these machines has made many industries a little more environmentally friendly.

Electric motors are a crucial component of robotics. While most robots use electric motors, they are available in different forms. In industrial robots, these motors are commonly brushed DC or brushless AC models. The latter is preferred for lighter loads or rotational motion. They also are more compact. If safety is a concern, another option is wind power, which uses turbines. This energy source can be renewable, and can be generated from the anaerobic digestion of organic waste. Advancements in computing power and software development have made robot assembly simpler and faster. Previously, actuators and sensors needed to be connected individually to the robot controllers. Today, network wiring connects sensors and actuators. These components are often auto-identifying so that the entire assembly process can be performed more quickly and efficiently. Furthermore, sensors and actuators can collect data and report on their status, saving time and money on maintenance. The use of advanced robotic technology is transforming the industry